RISOGRAPH 孔版印刷

是一種獨特的印刷技術,類似絹印和版畫,通過在滾筒上形成模板,將油墨高效轉印到紙張上。

與傳統的CMYK四色印刷不同,我們提供多達23種顏色的油墨選擇,包含螢光色、金色等。不需要大量印量即可印刷,特別適合少量且個性化的出版物,從50到一萬份皆可提供!

RISOGRAPH 孔版印刷的魅力在於其鮮豔的色彩和偶爾的“任性”效果,這種不確定性有時能為創作者帶來意外的驚喜,成為表達創意的一種獨特方式。自從在日本普及後,許多學校和小型印刷店都使用RISOGRAPH,成為中小型印刷需求的理想選擇。

RISOGRAPH printing is a unique printing technique, similar to screen printing and printmaking, where a template is created on a drum and ink is efficiently transferred to paper.

Unlike traditional CMYK four-color printing, we offer up to 23 ink color options, including fluorescent colors and metallic gold. There is no need for large print runs, making it ideal for small, personalized publications, with quantities ranging from 50 to 10,000 copies!

The charm of RISOGRAPH lies in its vibrant colors and occasional “quirky” effects. This unpredictability often brings unexpected surprises for creators, offering a unique way to express creativity. Since it became popular in Japan, many schools and small print shops have adopted RISOGRAPH, making it the perfect choice for medium and small-scale printing needs.

RISOGRAPH 特色

|

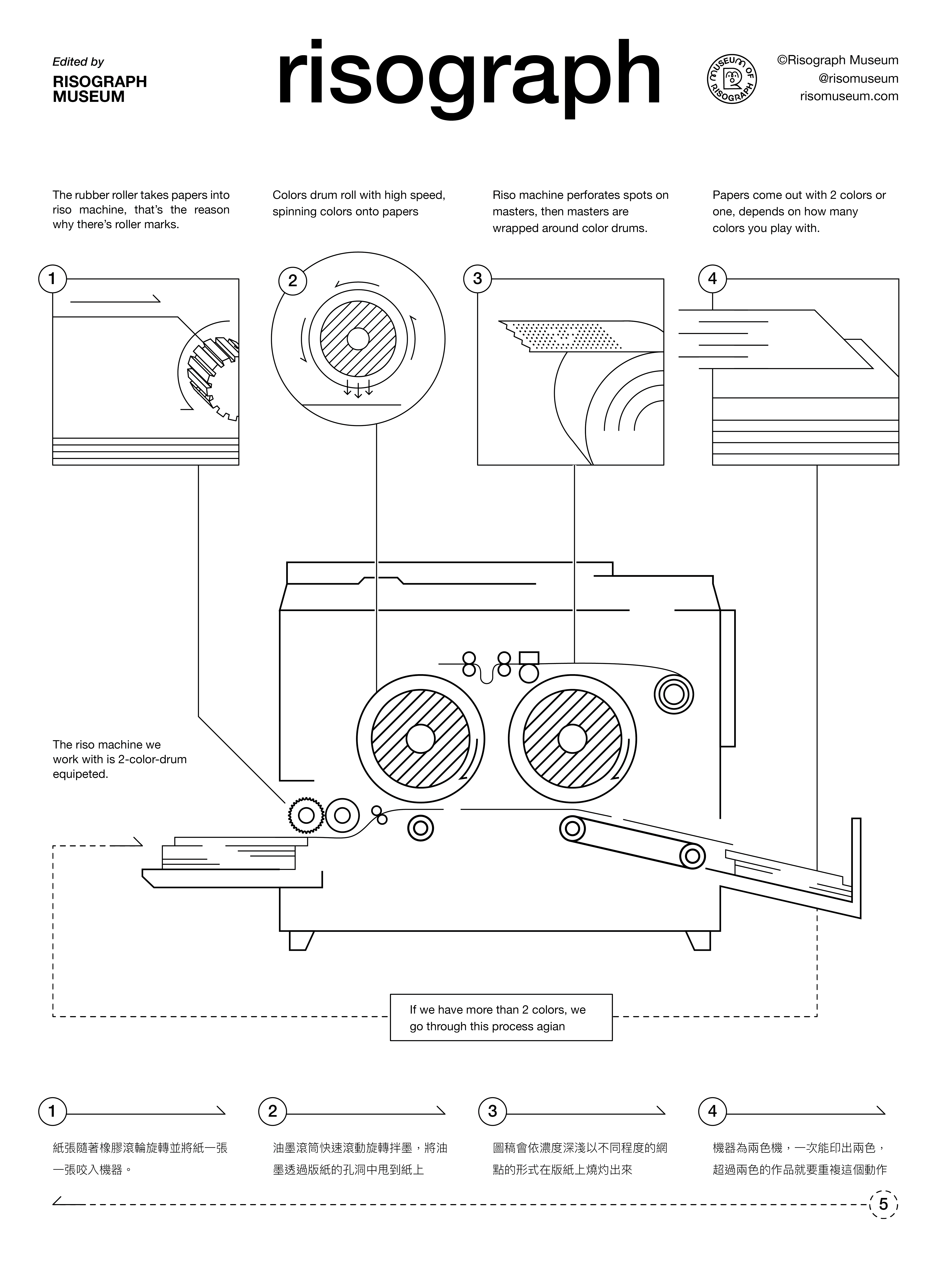

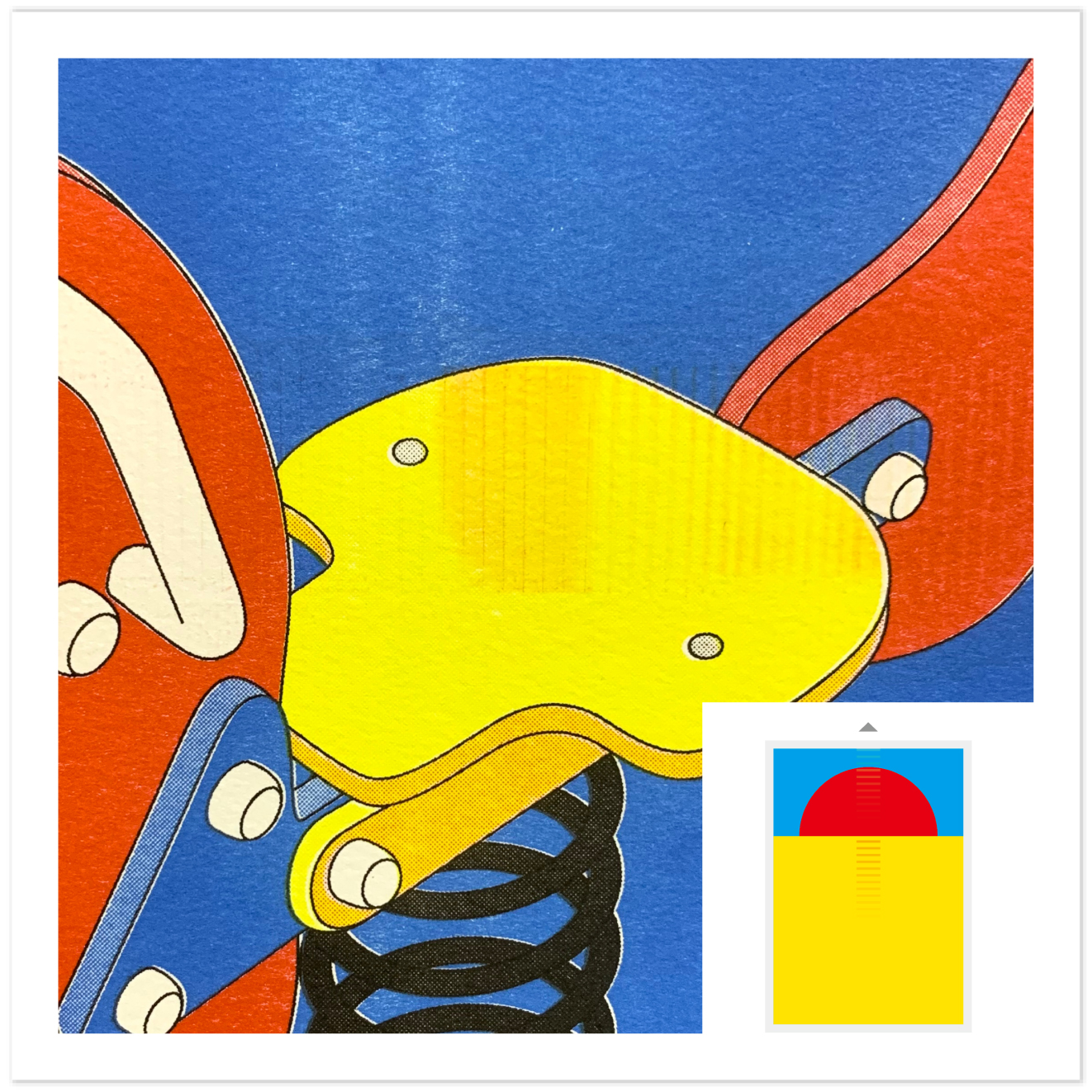

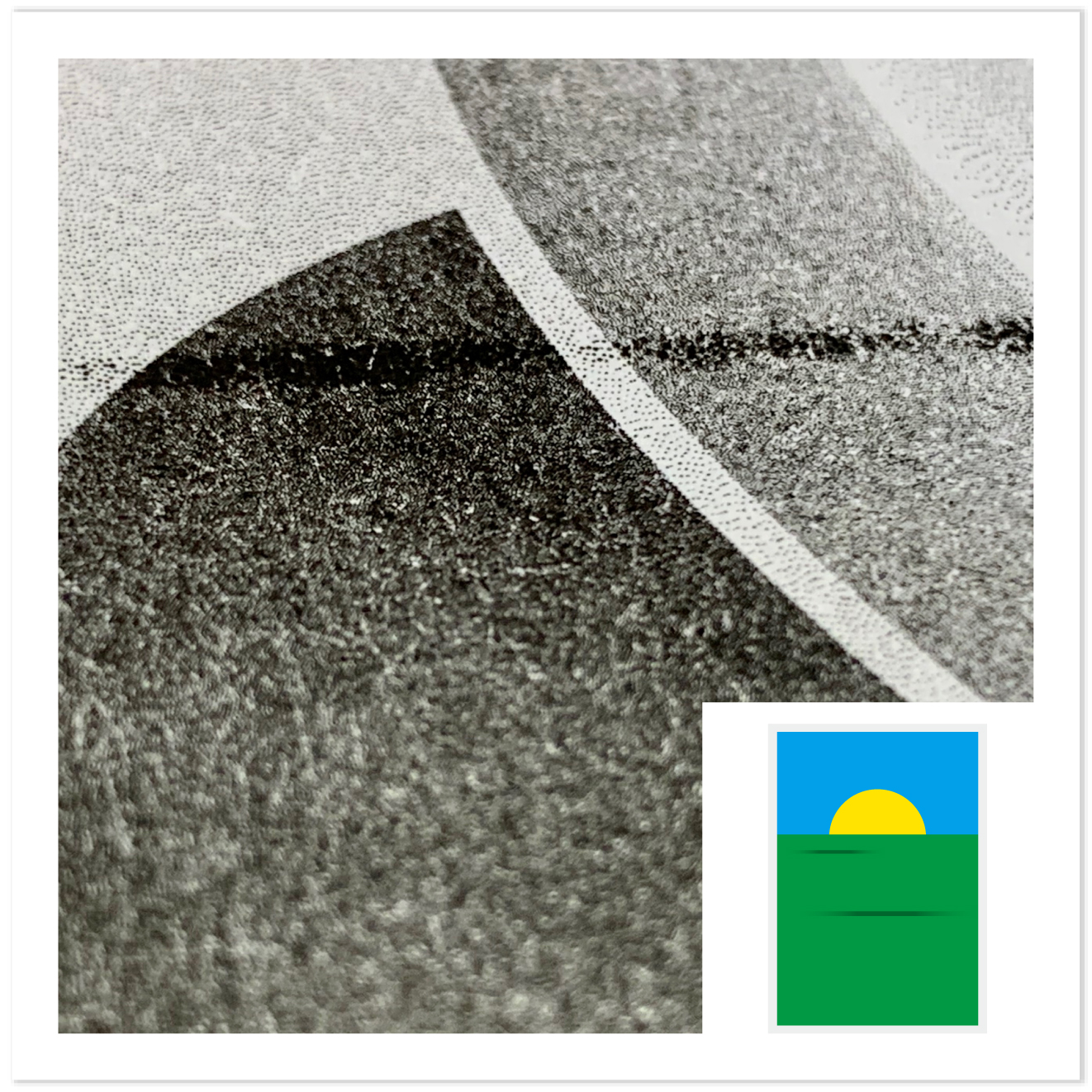

錯位 Misregistration

孔版印刷必定會有些微的錯位,每一張印刷品不可能都完全一致。孔版印刷機器一次只能印製兩色,每個顏色都需要手動對位,因此如果需要非常精準的印刷品,則需要慎重考慮是否要選擇Risograph印刷。不過其實錯位這種不確定因素造成的每一張都有點不相圖的獨特性,反而是很多人選擇孔版印刷的原因呢。

Every 2 color layer is printed individually, so colours rarely line up perfectly on top of each other. This gives Riso’s distinctive misregistration an unavoidable part of the process. This is an inherent part of the process that makes each print totally unique. If you are open to imperfections and experimental result, Risograph printing will be perfect for you! |

|

摩擦掉色&大面積墨色不均 Smudging

Riso ink is made of soy or rice oil. Which is environmentally-friendly. This type of ink stays open many hours after printing and will smudge if enough pressureIs applied to it. |

|

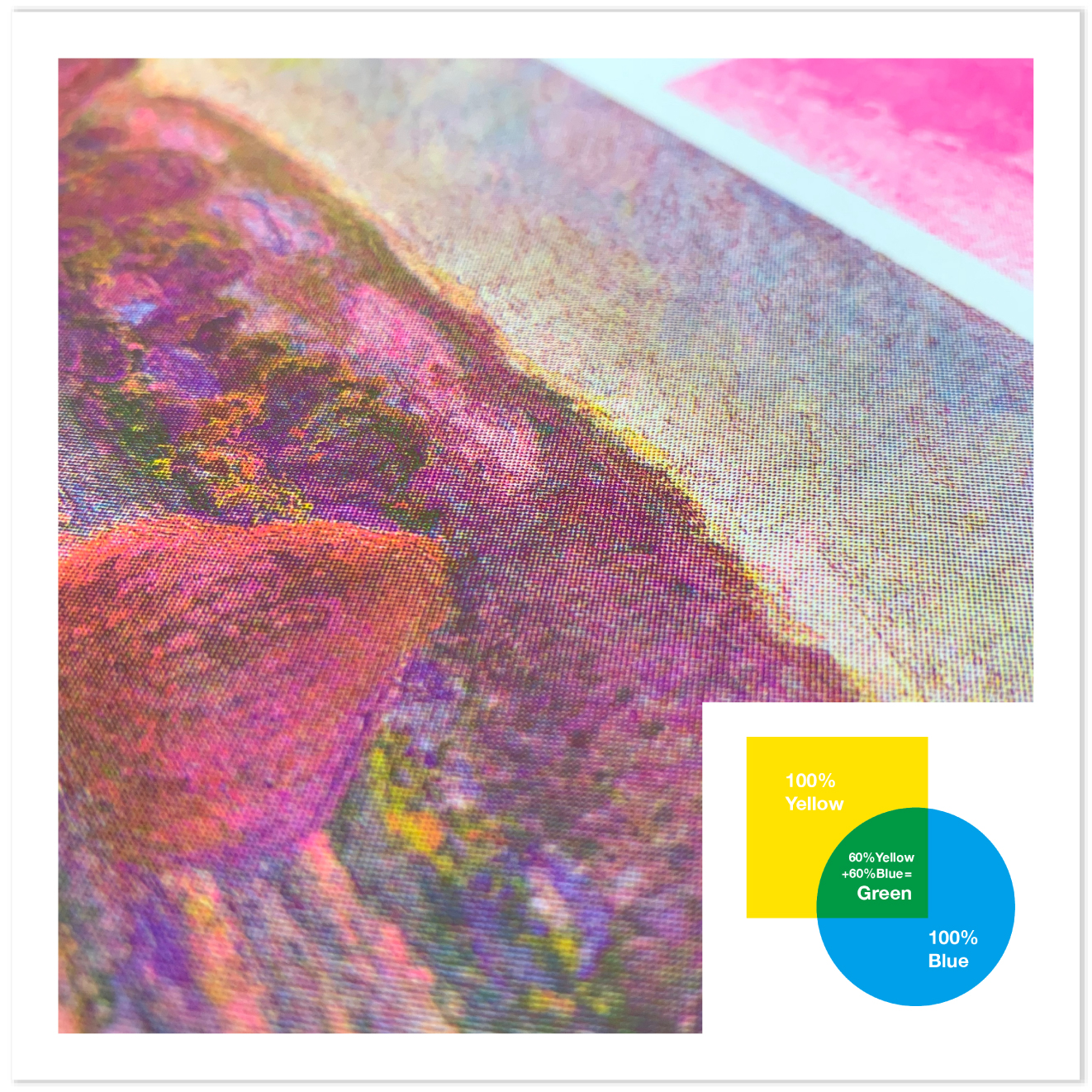

混色 Color Overlapping

多色印刷時會因印刷順序產生不同效果,工作人員會依成果最好的順序去印製,建議混色時可以先跟工作人員討論,或是先試印確認效果後再進行調整或大量印製。 With colors overlapping, it's fun to have surprising results. Like all we know that overlapping yellow and blue would produce green. And yet with different density or different yellow and blue, you can have variety of green. For instance, we have 3 kinds of yellow and 4 kinds of blue, how many tone of green would you probably get? |

|

色塊&水痕 Uneven Coverage

基本上所有墨色都會出現色塊問題,但深色的墨色會較為嚴重。 Sometimes, there will be some uneven coverage of colors appear on prints. This situation happens especially if you print with high color intensity and large area. |

|

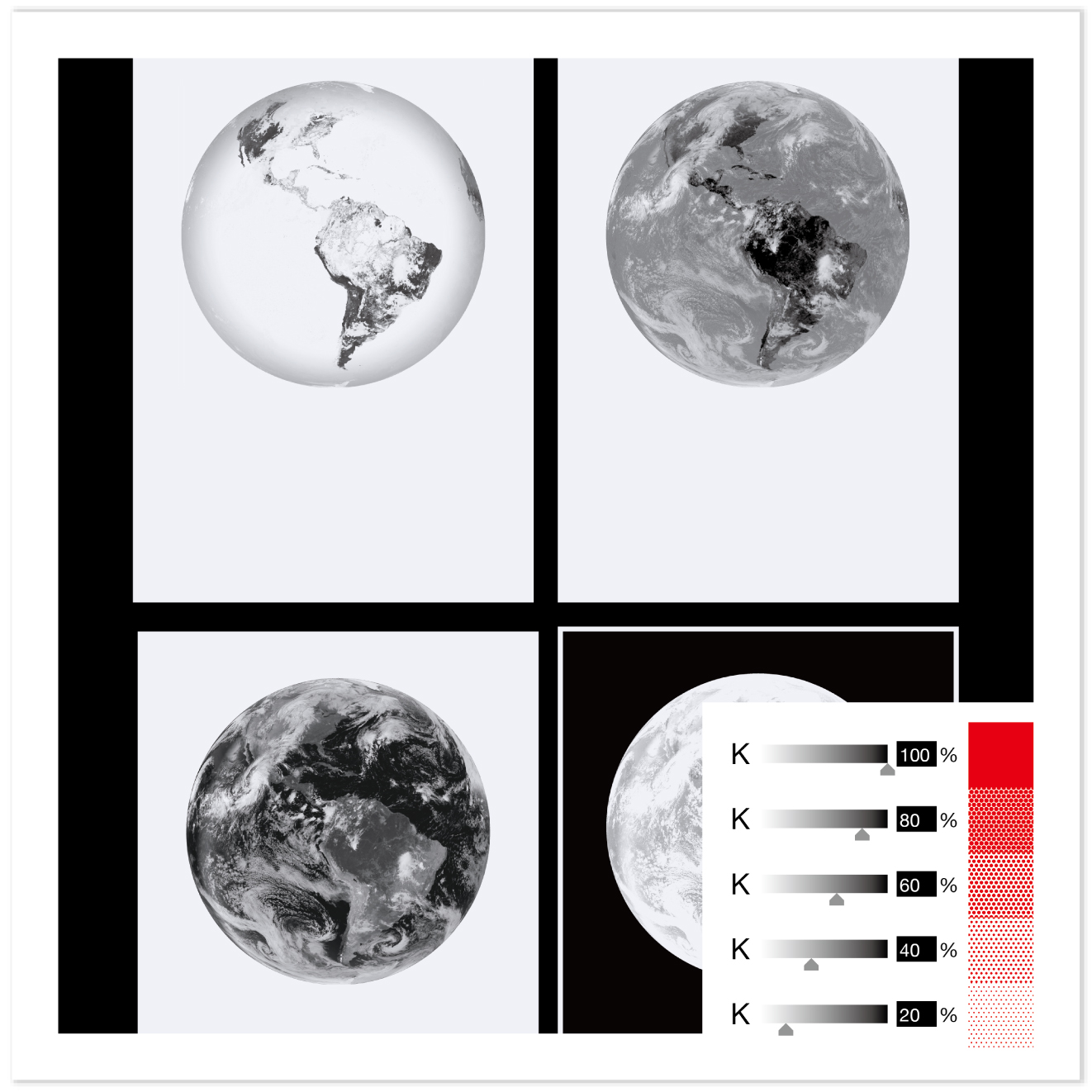

黑白稿入檔並選擇顏色

如右圖以是以黑白入檔,並選擇印刷成紅色,黑色的濃度即會決定顏色的濃度。 強烈建議黑白入稿時CMY皆為0,調整K的數值即可,詳細示意圖請見「原稿製作教學頁」(示意圖並非印刷效果)。 The file for the Risograph must contain only grayscale information and will be transformed into halftones automatically by the RIso. Each file can contain different gray values. 100% black in each color layer, will print out as 100% of whichever color you are printing. 60% black will print as 60% and so on.

|

|

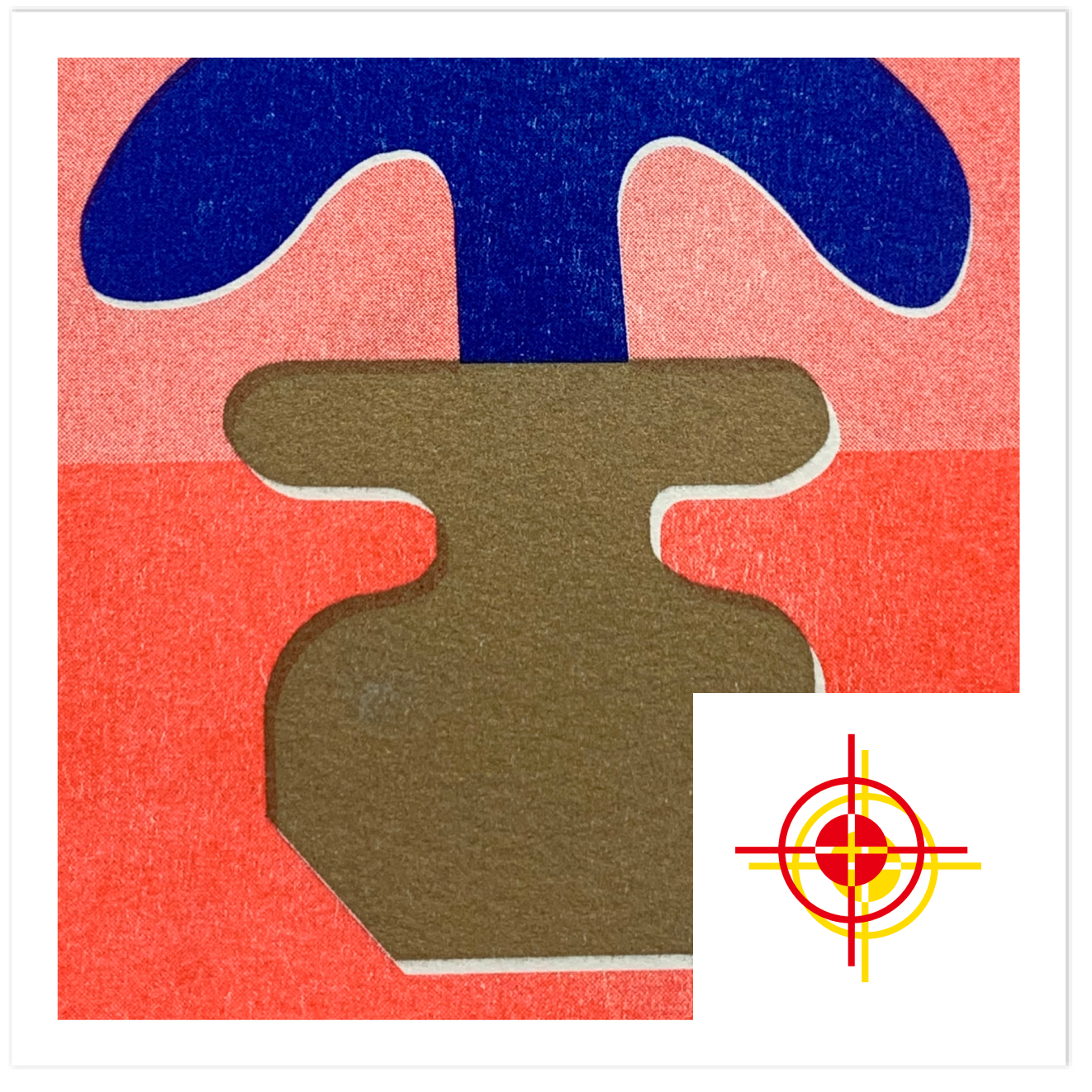

滾輪印 Roller Marks

紙張是通過滾輪送到印刷機進行印製,由於油墨有不會立即乾燥的特性,油墨容易附著在滾輪上。調整印製程序及擦拭滾輪可以減輕滾輪印,但如果印刷是大面積圖形或者是色版中間有高濃度油墨時,滾輪痕跡則無法避免。 Paper is fed through the Risograph with a rubber wheel. This applies pressure to ink, which can leave a mark on your artwork. For artwork with heavy ink coverage, roller marks may occur in the area shown in this graphic aside. |

|

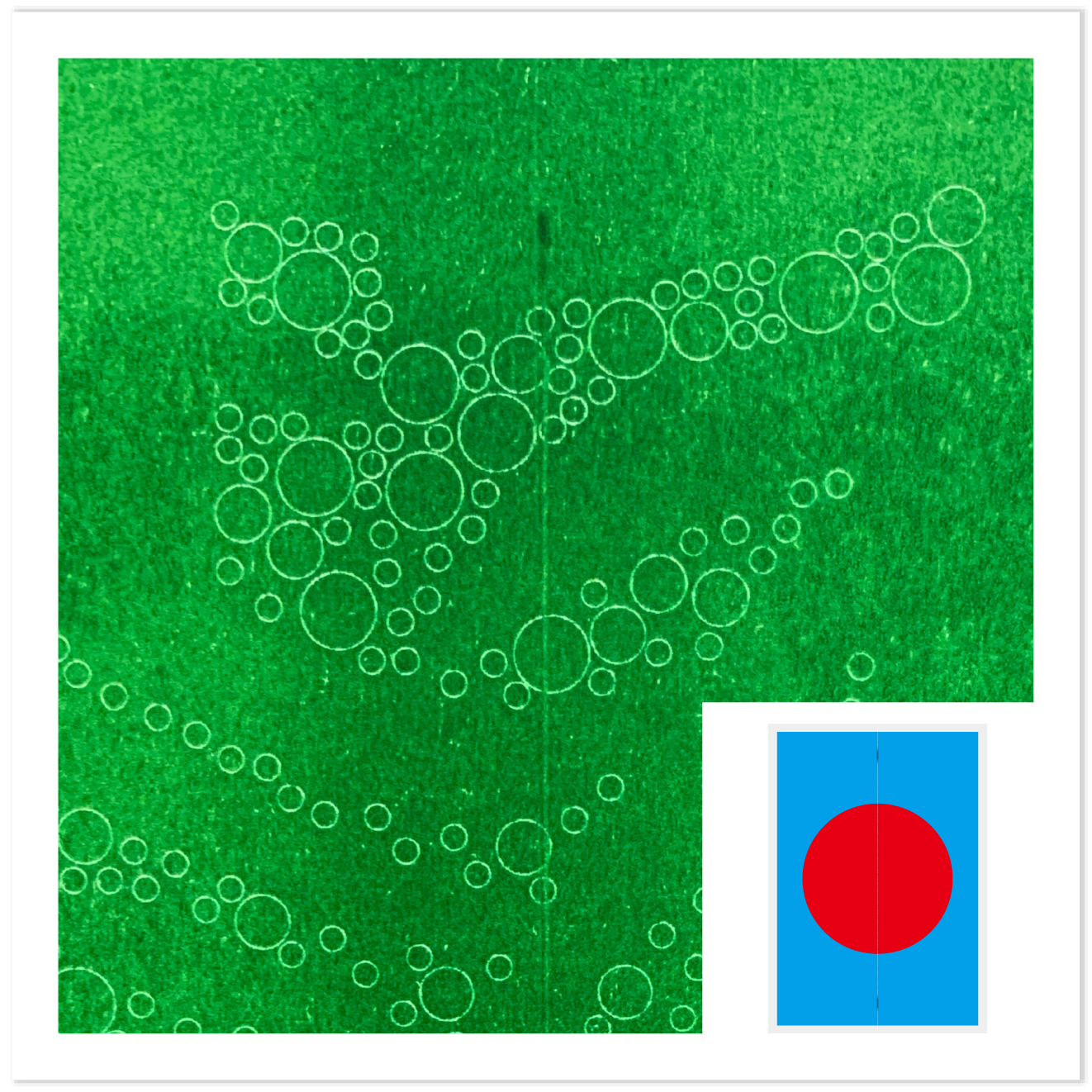

針跡 Pin Marks

若油墨用色範圍較大且濃,紙張容易沾黏在滾筒的版紙上,為了能順利送紙,孔版印刷機內的「細針」會將濕黏的紙張脫離滾筒,而針所劃過的一條線痕則稱為針跡。 對此若較為介意,建議可以減少油墨的使用面積或降低油墨濃度。 If the ink coverage is large and dense, the paper is prone to sticking to the plate cylinder. In order to facilitate smooth paper feeding, the "fine needles" inside the perforation press will detach the wet, sticky paper from the cylinder, and the line left by the needle is called a needle mark. If this is a concern, it is recommended to reduce the ink coverage or decrease the ink density. |

|

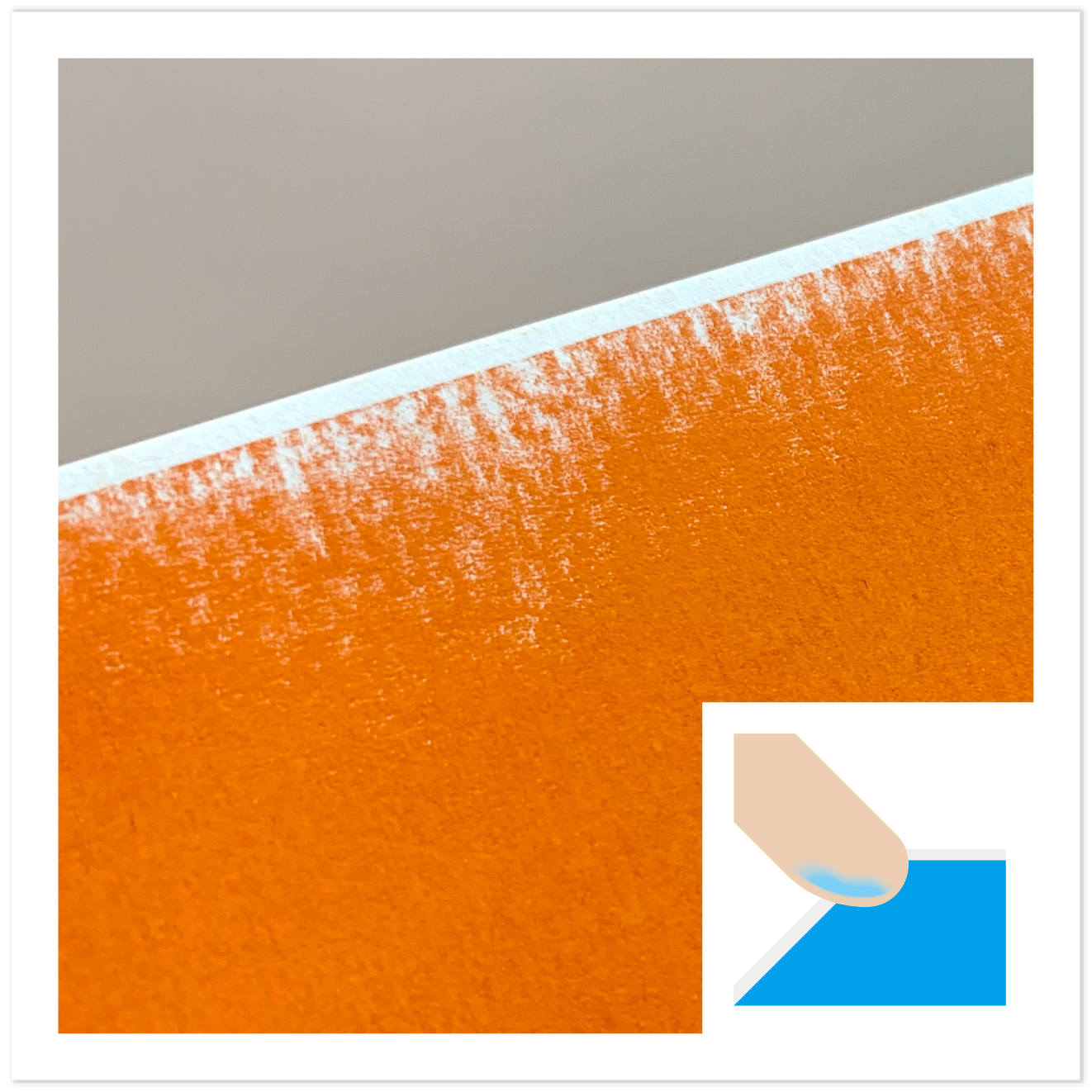

墨跡 Ink Marks

版紙附著在油墨滾筒上,因此本身的紋路與產生的曲折就是產生墨跡的原因之一,尤其是濃度高且面積大的稿件,在印刷時容易出現像水波般的墨痕,而深色的墨色較為嚴重。 雖然出現的機率難以預期,但減少色塊面積能夠降低產生墨痕的風險。 The paper adheres to the ink roller, and its own texture and creases are one of the reasons for ink smudging. This is particularly common with artwork that has high ink density and large coverage, often resulting in wave-like ink marks during printing, with darker ink colors being more pronounced. Although the occurrence rate is difficult to predict, reducing the size of ink areas can help minimize the risk of ink smudging. |

|

雙面印刷壓痕 Stress Marks

當雙面印刷時,其中一面用色面積較大,進紙時機器會摩擦到已印製的圖稿,導致下張紙印刷時邊緣會沾染到油墨。 When printing double-sided, if one side has a larger ink coverage, the machine may rub against the previously printed artwork during paper feeding, resulting in ink smudging on the edges of the next sheet during printing. |

|

紙背邊緣破損 Broken of Paper

多色印刷以及紙張磅數較高等等,在印刷機送紙時容易磨損紙張,造成紙張背後產生邊緣破損。 Factors such as multi-color printing and higher paper weight can easily cause paper wear and tear during paper feeding in the printing machine, resulting in damage to the back edges of the paper. |

|

RISOGRAPH PRININTING,孔版印刷

1946年 羽山昇 於東京成立了一間蠟紙印刷店 在他發明了第一台Risograph孔版印刷機後 這家小小的印刷店在1963年正式更名為RISO KAGAKU工業株式會社 羽山昇會如此命名是有其意義的 在日語中「RISO」是理想的意思,而「KAGAKU」則是科學 所以這家公司也可稱作「理想科學」工業株式會社 |

Noboru Hayama, the Inventor of the Risograph machine, started his business in 1946.

He established a mimeograph printing company in Tokyo, Japan. After Mr.Hayama invented the first RISO printer duplicator, this printing store changed the name of the company to “Riso Kagaku Corporation”. In Japanese speaking, “Riso”means “ideal” and “Kagaku” means “science”. |